From Our Hands to Yours

At Ruffs, every ring is crafted on a foundation of patience. For over 120 years, we have refused shortcuts in favour of mastery. Each piece is cast, engraved, and finished, not for speed, but for permanence.

Where the Story Begins

Each Ruffs ring starts, not in our workshop, but in conversation. With choices of shape, size, weight, metal, and engraving, no two journeys are ever the same. These decisions - sometimes practical, often deeply personal - set the course for the piece to come. From that moment, our craft begins.

CASTING

Substance from Fire

Once chosen, each ring takes form as molten gold is cast into a mould unique to that order. Depending on the chosen form, this will take place either in Birmingham's renowned Jewellery Quarter, or with our master craftspeople in Norfolk. Some customers bring old family gold to be reborn; others select new metal. In either case, casting allows us to control every detail - shape, weight, proportion - and ensures that every ring is of equal substance and elegance.

HALLMARKING

The Maker’s Signature

Next, each ring travels to the Sheffield Assay Office, where it is hallmarked - a legal requirement, and a legacy in itself. Inside every band you will find four marks:

- CNAR:

Our maker’s mark, for Cyril Norman Aubrey Ruff. - The Sheffield Rose:

A symbol of where every ring is tested and assayed. - The Metal Mark:

An Imperial Crown and purity number (9, 14, 18 or 22ct). - The Date Letter:

A single letter marking the year of creation.

Together, these are more than symbols - they are the ring’s permanent record, carried forward for generations.

ENGRAVING

Stories in Detail

In the third stage, the ring is sent to our trusted engravers - small, family-run workshops we have partnered with for generations. Apprenticeships here can last a decade, and their methods are centuries old.

Customers may choose from:

- Seal Engraving:

Cut in reverse to leave a raised wax impression - Deep Carving:

Deep Carving: Cut deep like a seal, but in the positive. Often used for monograms or crests - Surface Engraving:

Lighter, elegant lines, often initials

POLISHING & FINISHING

A Quiet Art

No piece leaves our hands without being polished and finished. This stage takes time and restraint: removing what should be removed, refining what should remain. The aim is to find a careful balance so that when the ring is worn, its comfort is matched by its quiet brilliance.

THE FINAL STAGE

A Lasting Impression

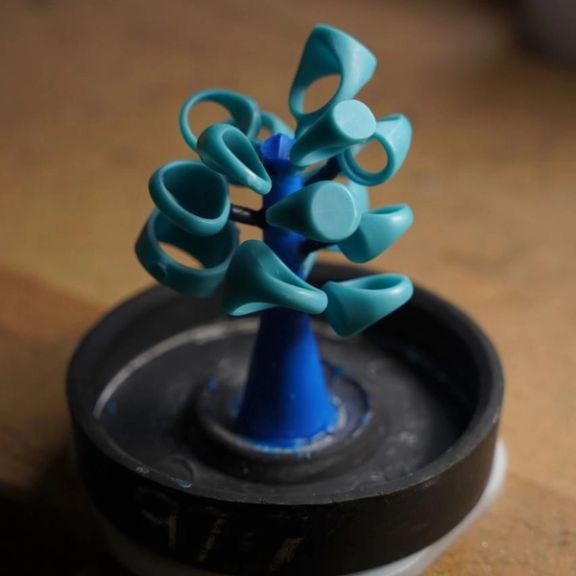

With engraving complete, each seal-engraved signet ring is accompanied by its wax impression: a carefully taken seal that proves the depth of the engraving and gives the customer their own mark.

Ring and wax seal are then placed together in sustainable packaging, ready to be delivered, unboxed, and one day passed on.

Make a Lasting Impression

A ring for today, a modern heirloom for tomorrow. Not just jewellery, a lasting impression.

Design your Ring

Design your Ring